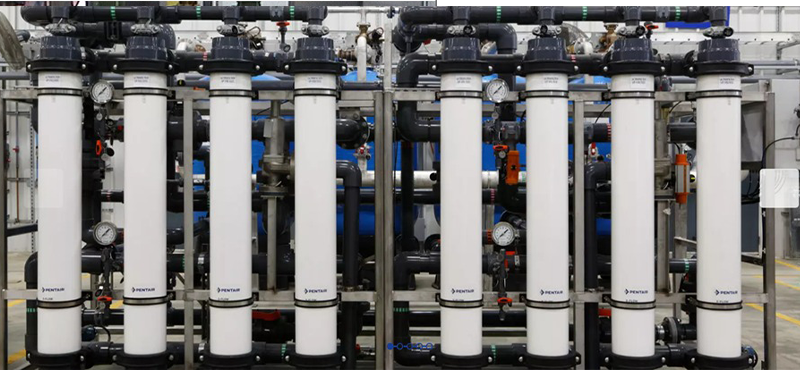

Ultra Filtration System

Ultrafiltration (UF) is a type of physical separation that uses a membrane with precisely sized openings to filter certain solid particles or large molecules out of a liquid stream. In addition to UF, there are other types of membrane filtration, including micro filtration, nano filtration, and reverse osmosis. all of which have distinct pore size ranges, and are thus suited for separation of various contaminants based on particle size. With pore sizes ranging from 0.001 to 0.1 µm in size, UF is suited for separation of very fine particles, which can include silica, silt, endotoxins, plastics, proteins, smog, and viruses.

Form a conceptual standpoint, ultrafiltration is a fairly straightforward process that basically consists of passing a liquid stream through a porous membrane. Any particles that are larger than the pores in the UF membrane are unable to pass through, and in this way, UF is said to work based on the principle of size exclusion. Depending upon the type of UF unit used, these larger constituents can become a concentrated liquid stream known as the retentate, or they may collect on the surface of the membrane as a solid known as a filter cake. The liquid portion of the stream, and smaller particles that are able to pass through the UF membrane, are referred to as the filtrate or permeate stream.

Dead-end vs. cross-flow filtration:

Fluid dynamics, or the way in which a liquid moves through a water treatment system, are especially important to the design of an ultrafiltration system. There are two main flow pattern configurations for UF systems—dead-end filtration and cross-flow filtration. Ultrafiltration proceeds in fundamentally the same manner in both types, however, there are some key differences between the two that make either approach more or less suitable for certain applications.

Also known as direct flow filtration, dead-end filtration is a type of membrane separation where the feed stream is forced through a porous membrane at a perpendicular angle. Particles that are too large to fit through the membrane pores build up on the surface of the filter in a residue known as a filter cake. As the filter cake layer accumulates, the high concentration of contaminants on the surface of the membrane can result in decreased permeate flux, or in other words, a decline in the flow of the solvent liquid through the membrane. For this reason, dead-end filtration is generally used for batch or semi-continuous flows, allowing the membrane to be cleaned between use cycles to remove filter cake buildup. Dead-end filtration provides a high recovery rate of the feed stream, typically over 95%, and is well suited for streams with a low concentration of particulates, or in applications where a purified filtrate stream is needed.

A different operational design type, cross-flow filtration is a type of membrane separation where the feed stream flows along the surface of the membrane at a parallel angle. Otherwise known as tangential filtration, cross-flow systems produce two liquid streams, including both a purified filtrate stream, and a concentrated retentate stream that is usually recirculated through the UF unit. Cross-flow filtration is typically operated as a continuous process because the constant flow of the feed stream across the surface of the membrane prevents the accumulation of solids on the surface. This characteristic has several implications, including little to no filter cake formation, less frequent cleaning needs, a longer membrane lifespan, and more consistent flux. However, because the retentate is reciculated, cross-flow systems tend to consume more energy, and offer a lower feed stream recovery rate compared to dead-end filtration. As such, cross-flow filtration is best suited for treating feed streams with high concentrations of solids, or for applications where a concentrated retentate solution is needed.